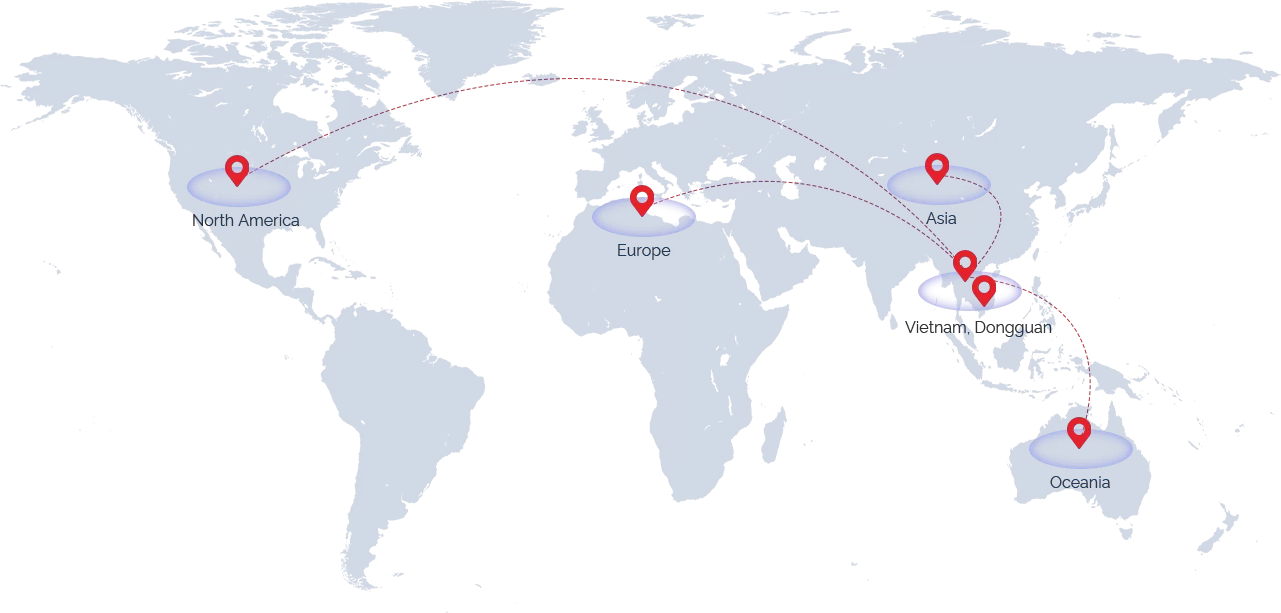

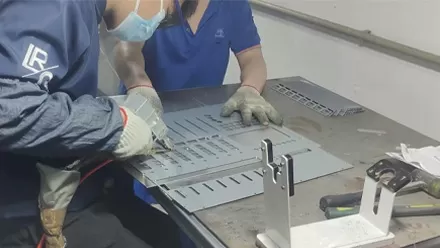

Pinzhihao Precision offers a wide range of sheet metal manufacturing services, including bending, welding, laser cutting, punching, and more. Choose Pinzhihao as your partner and experience services that exceed expectations.

In our bending services, we employ precise techniques to ensure accurate folding of sheet metal parts, guaranteeing the final product's accuracy and stability. Whether dealing with simple components or complex structures, we can address various challenges to meet your personalized requirements.

Welding is a crucial aspect of sheet metal manufacturing, and Pinzhihao boasts a skilled welding team that ensures the strength and stability of welded joints. We prioritize attention to detail, striving to provide high-quality welding services that meet your demands for structural strength and durability.

Laser cutting is another strong suit at Pinzhihao. Through advanced laser technology, we achieve precise cutting of various materials, ensuring dimensional accuracy and surface quality for your parts. This offers increased manufacturing flexibility and accuracy for your projects.

Punching services at Pinzhihao are a valuable asset in sheet metal manufacturing. We can fulfill various requirements for hole punching in terms of shapes and specifications, enhancing the diversity and practicality of your parts' design.

Choosing Pinzhihao as your sheet metal manufacturing partner will benefit you with our outstanding technology, professional team, and diverse services, ensuring your projects achieve results that go beyond expectations. We look forward to being your supporter in success, collaborating to create excellent sheet metal manufacturing solutions.